Basic elements of an Engineered Truss Bridge :

The spaghetti bridge is made up of the basic geometric shapes ...squares and triangles. If you look around you , these can be seen in many places.

|

| Example of a Truss Bridge |

The Bridge is made up of 4 elements

1 Bottom Structure

2 Top Structure

3 Left Side

4 Right side

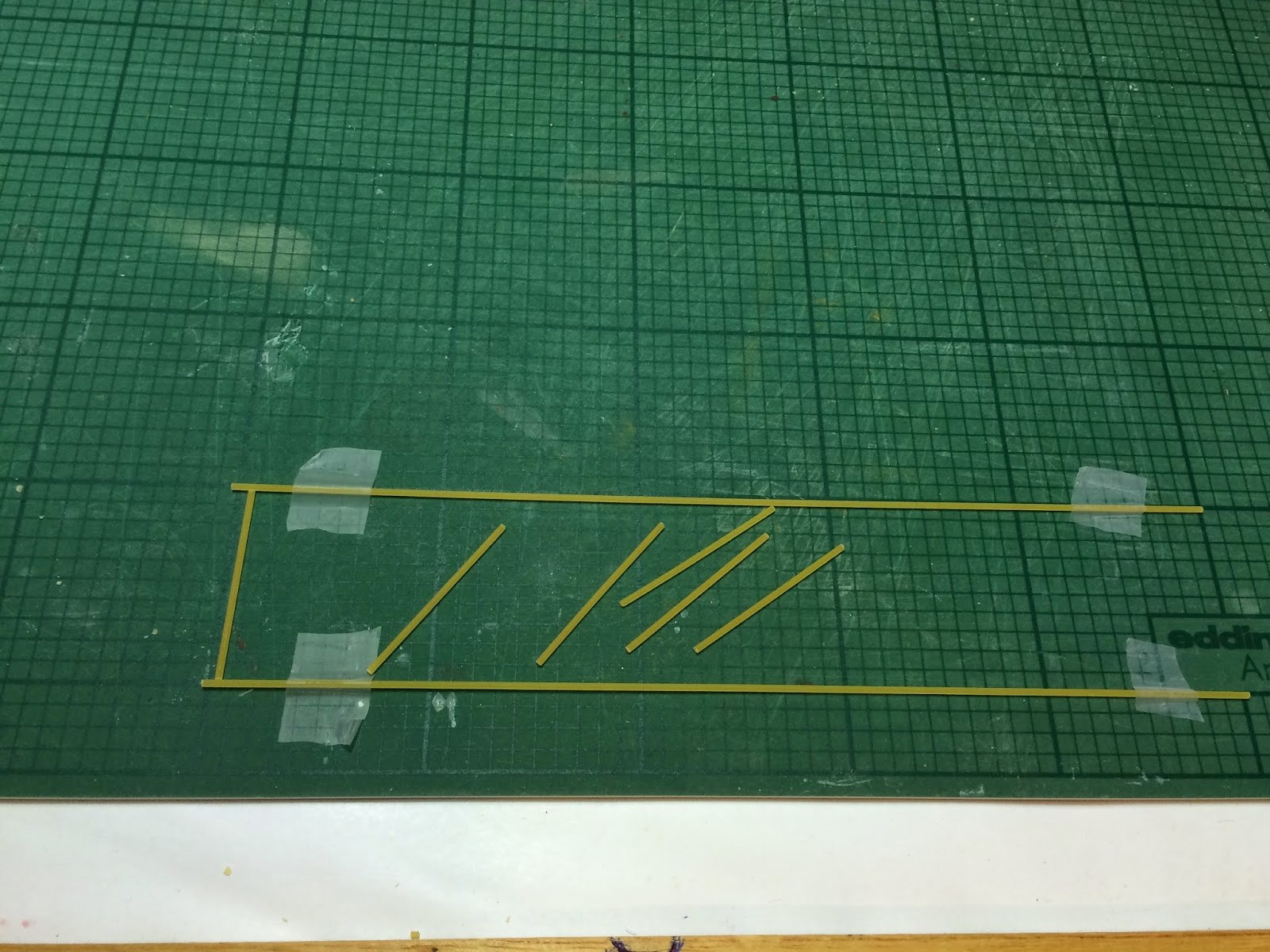

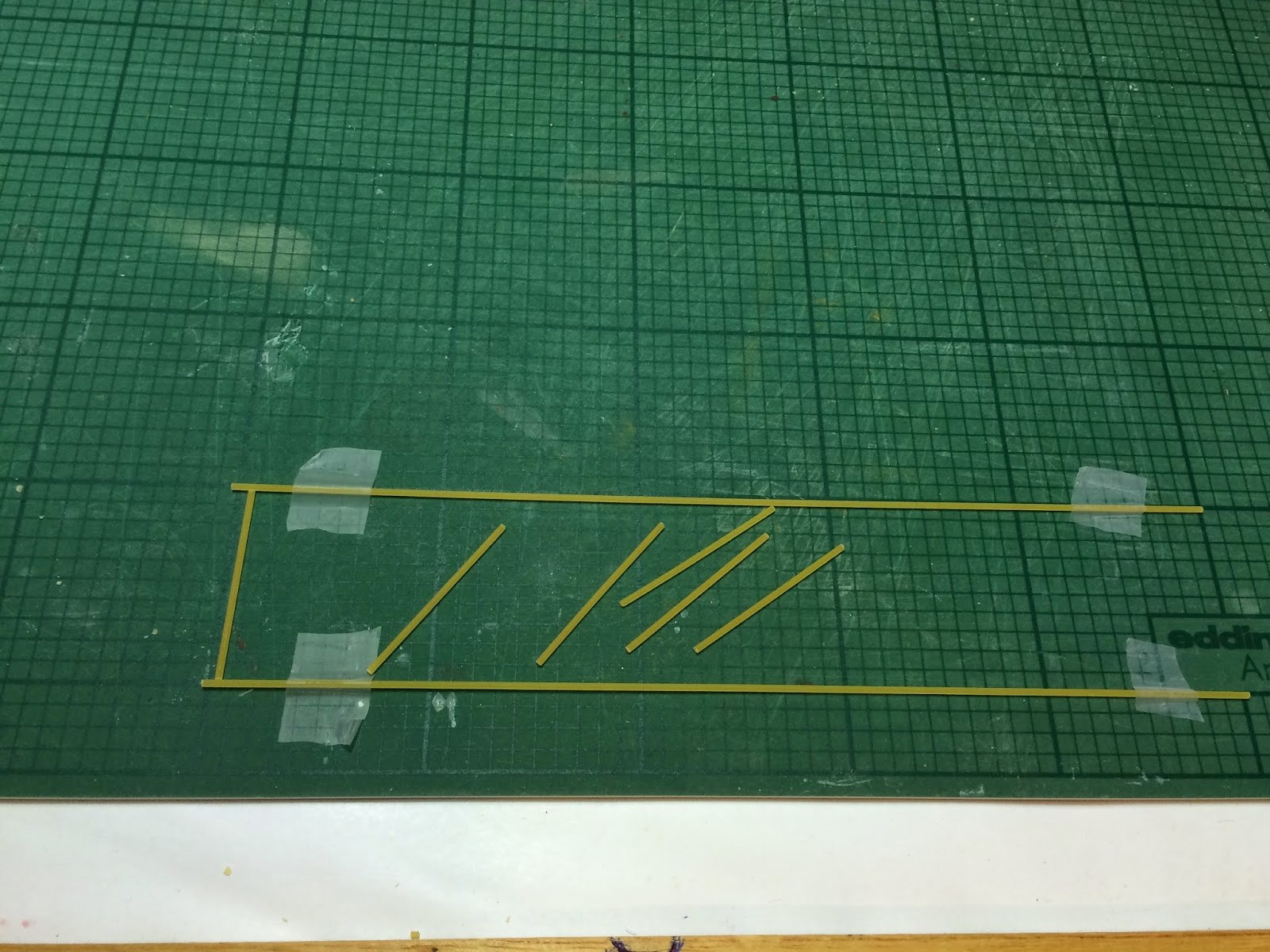

STEP 1 - BOTTOM STRUCTURE

Cut two lengths of spaghetti to 250mm long and tape down to work surface with a 50mm spacing between them.

|

| Main supports for Bottom Structure |

Cut six pieces 50mm long to act as cross braces.

|

| Six cross braces, each 50mm long |

Align the cross braces starting at one end so they form five squares 50mm a side each.

|

| Cross braces positioned roughly in place. |

Once the position is OK, tape the cross braces to the work surface so they stay in place during the gluing operation.

|

| Cross braces taped in position ready for gluing |

Ensure the cross braces touch the 250mm long support pieces so that the glue joint can be tight.

|

| Close up of cross braces touching the outer supports. |

Pour some glue from the bottle into a small receptacle....an art pallet or old yogurt pot works well.

|

| Pour some glue into a small tray for ease of application |

A small amount of glue goes a long way so don't overfill the art pallet.

|

| A small amount of glue is enough to go a loong way. |

The glue can be applied by using a small paintbrush. Use an old one as it cannot be used for paint again after being used for glue. A small cocktail stick works just as well.

|

| Apply the glue using an old paint brush...the smaller the better. |

A small dap of glue should be applied to each joint.Let the glue seep into the joint. Run the brush down the sides a little but do not allow glue to stick the structure to the mat.

|

| A small amount of glue at each joint will hold the assembly together. |

If the sticky tape does not hold the spaghetti pieces well enough , additional support can be provided by using small blobs of blu-tac. Put it where-ever needed but not near a glue joint where it will get stuck to the assembly.

|

| For additional support a small blob of blu-tac can be used. |

Once the glue has dried a little and the joint has taken some strength, approx 1 hour, the diagonal braces can be added. Cut a length of spaghetti long enough to span the diagonal in the 50mm square...this will be about 71mm long.

|

| Diagonal pieces add strength but need to be fitted into the corners well. |

The ends of the piece should be shaped into an arrow point so they fit right into the corners of the square. This can be done with a sharp knife, a scalpel, a craft knife, etc.The better the fit into the corners of the square, the stronger the glue joint will be.

Continue through the squares with the end point of one diagonal being the start point of the next diagonal.Each diagonal piece needs to be a snug fit and should stay in the square even without glue. when all the diagonal braces are in place, the joints should be glued up as before.

|

| Ensure diagonals are a tight fit and glue up. |

Once the diagonals have dried a bit and the glue joints attained some strength, add the final diagonal in two short lengths. Each length going into the remaining corner and touching the existing diagonal at the centre point.

|

| Apply the first half of the final diagonal so it touches in the centre of the existing diagonal |

Adjust the second diagonal piece so it makes a straight line from corner to corner.

|

| Complete the final diagonal and glue up. |

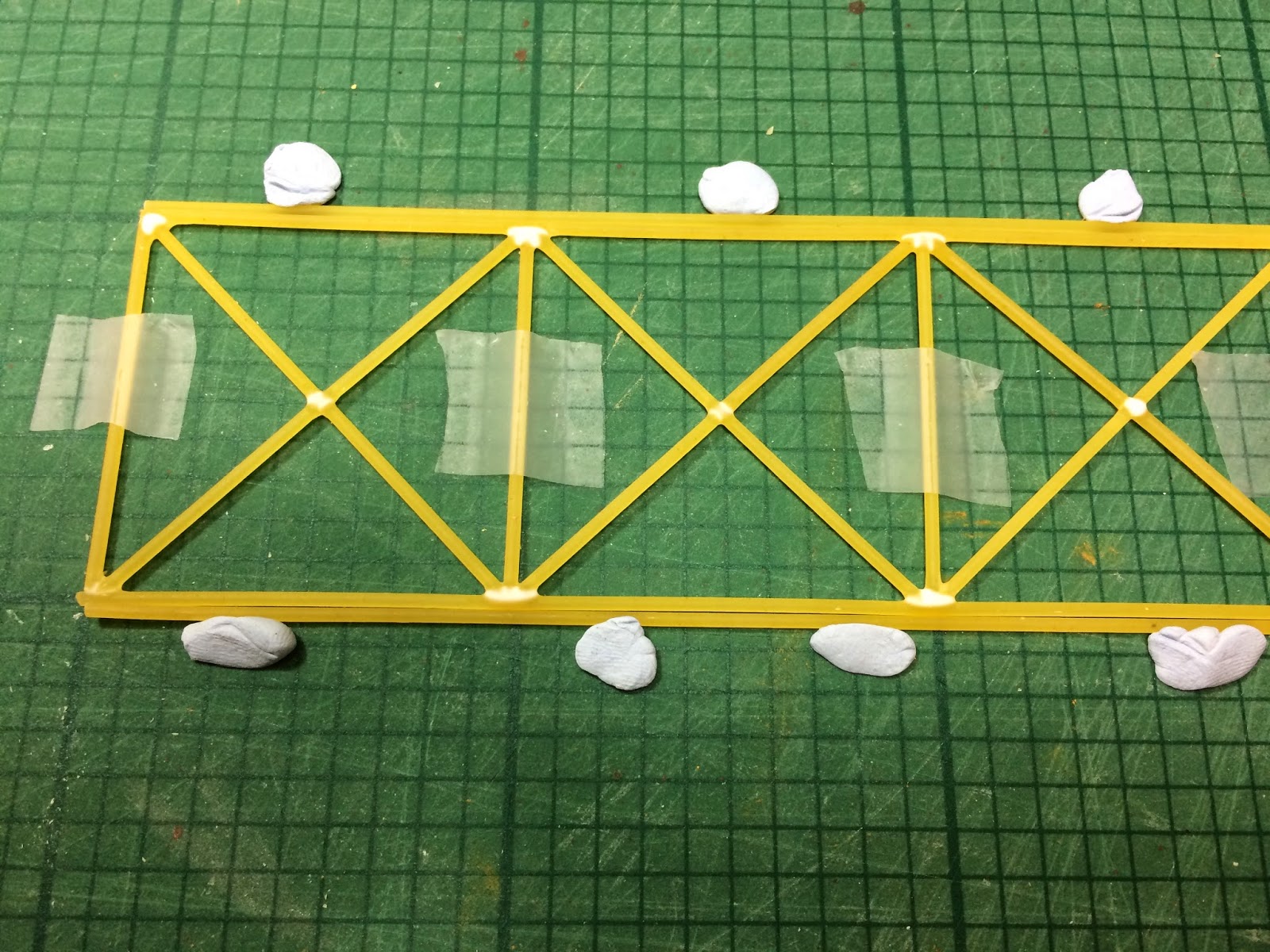

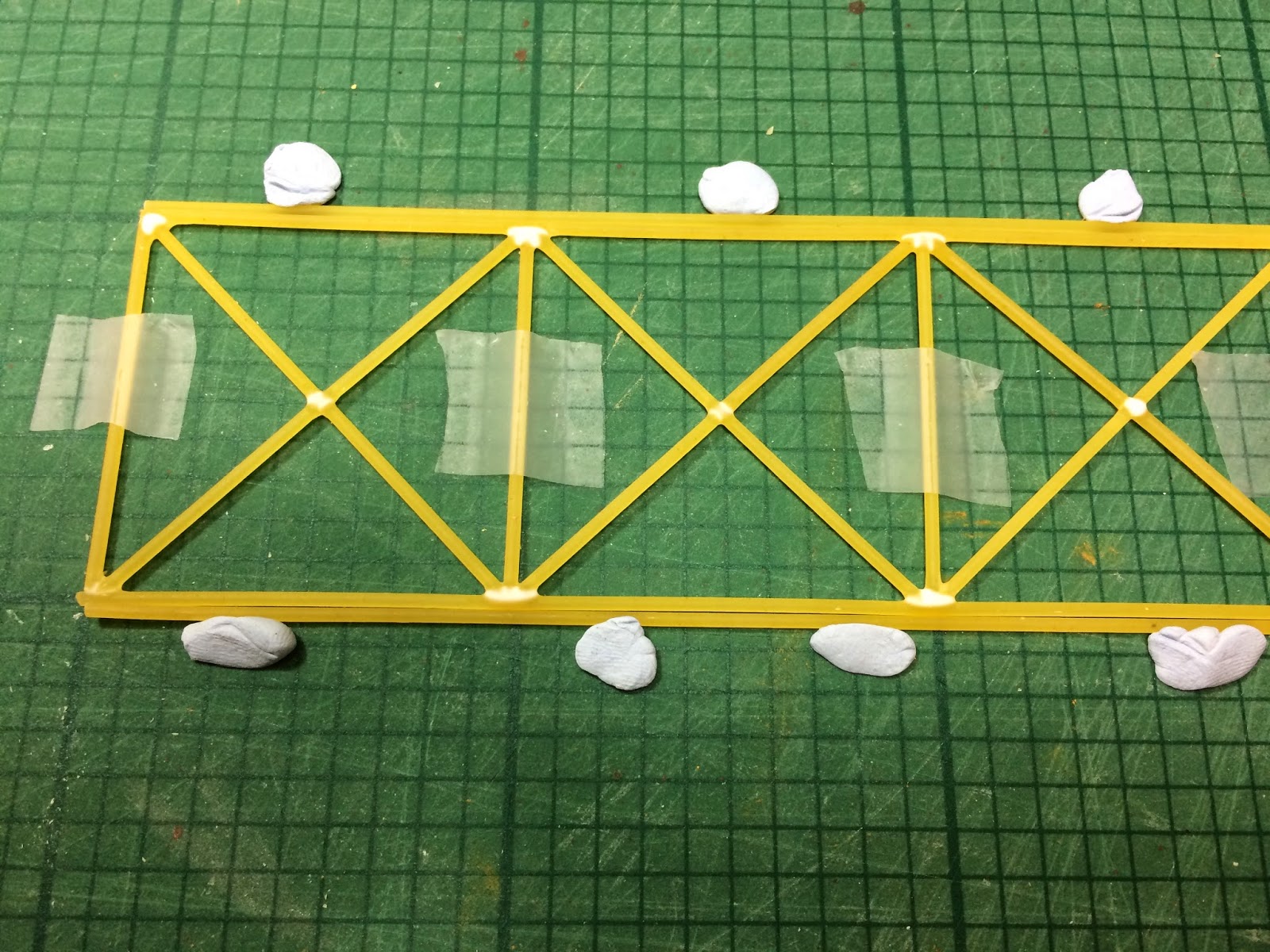

When completed there will be a full set of five squares with full corner to corner diagonal bracing. The strength of the bracing will come from a tight fit for all pieces.

|

| Full corner to corner diagonal bracing for maximum strength |

Once the full assembly is dry overnight, remove all the tape and blu-tac and flip the assembly over. Apply glue to all joints from the unglued side and allow to dry.

|

| Completed Bottom Structure...250mm long |

Once the basic structure is dry it is a good idea to strengthen the main supports. This will add strength but also allow a better platform for attaching the side pieces. Cut two lengths of spaghetti the same length as the base piece. Place the lengths alongside the assembled unit so it lies parallel to the long support element.

|

| Add two lengths in parallel to the long edges of the assembly |

Position the additional lengths in place and hold in place with small pieces of blu-tac. stick the assembly to the cutting mat with tape to hold it flat.

|

| Hold additional support elements in place with blu-tac pieces. |

Put enough blu-tac blobs along the length so the pieces are in close contact along the full length. This will aid gluing and ensure a strong bond.

|

| Push the additional pieces into close contact with the assembly. |

Run a string of glue all along the parts where possible , avoiding getting glue on the blu-tac.

|

| Run glue along the centre contact area of the two long spaghetti pieces. |

Allow to dry, then flip over and apply glue to the bottom side. Any spots where the glue was missed can be covered at this stage.